The induction motor or asynchronous motor always relies on a small difference in speed between the stator rotating magnetic field and the rotor shaft speed called slip to induce rotor current in the rotor AC winding. AC Motor Speed Synchronous speed is the absolute upper limit of motor speed. Ac motor winding design.

Ac Motor Winding Design, In general the AC copper loss can be reduced by increasing. Ac Electric Motor Design Software1. Since it is impossible for a technician to be in two places at once it is often necessary to perform diagnostic checks on a malfunctioning electric motor from the MCC where the technician has. In this section the AC and DC losses are analysed in Motor-CAD for increasing number of winding layers.

Electric Motor Design Basic Tutorial Windings From windings.com

Electric Motor Design Basic Tutorial Windings From windings.com

AC Motor Speed Synchronous speed is the absolute upper limit of motor speed. Softbit presents an easy way to design LT 3 ph TEFC squirrel cage ac electric motors with the help of AC Electric Motor Design Software. D L are in Meters min 025 mm For medium rating machines 2 3 mm Our effort is to keep the length of the air gap as small as possible. Resistances of three winding should be same - 5.

Easy to predict motor performance for a three-phase motor windings notoriously difficult for a single-phase designs.

Read another article:

A Shaded Pole motor is an AC single phase induction motor. Specific emphasis will be given to pump applications. Measure resistance for each winding resistance between two different winding and resistance between winding and motors frame. Designs A and B. The auxiliary winding which is composed of a copper ring is called a shading coil.

Source: youtube.com

Source: youtube.com

Thus a high value of ac is restricted because of temp rise over load capacity and voltage of the winding as discussed above. Softbit presents an easy way to design LT 3 ph TEFC squirrel cage ac electric motors with the help of AC Electric Motor Design Software. The calculation will be performed for the air-cooled three-phase motors for. The following design details are required. Single Layer 3 Phase Induction Motor Winding Diagram For 24 Slots 4 Poles Youtube.

Source: what-when-how.com

Source: what-when-how.com

The motor like squirrel cage can be frequently on track by the star to delta stator thus the stator of the motor can be connected in delta. AC Induction Motor Construction and Performance. Thus a high value of ac is restricted because of temp rise over load capacity and voltage of the winding as discussed above. Resistances of three winding should be same - 5. Stator Winding Design Considerations Electric Motors.

Source: jmag-international.com

Source: jmag-international.com

This tutorial will introduce the user to the fundamental electrical and mechanical principles of AC electric induction motor design and application. Cooling is necessary to continuously transfer the heat to a cooling medium such as the air. The shape and dimensions of a winding are designed to fulfill the particular purpose. Introduction to Design The main purpose of designing an induction motor is to obtain the complete physical dimensions of all the parts of the machine as mentioned below to satisfy the customer specifications. No 14 Synthesis Of Ac Motor Windings Simulation Technology For Electromechanical Design Jmag.

Source: researchgate.net

Source: researchgate.net

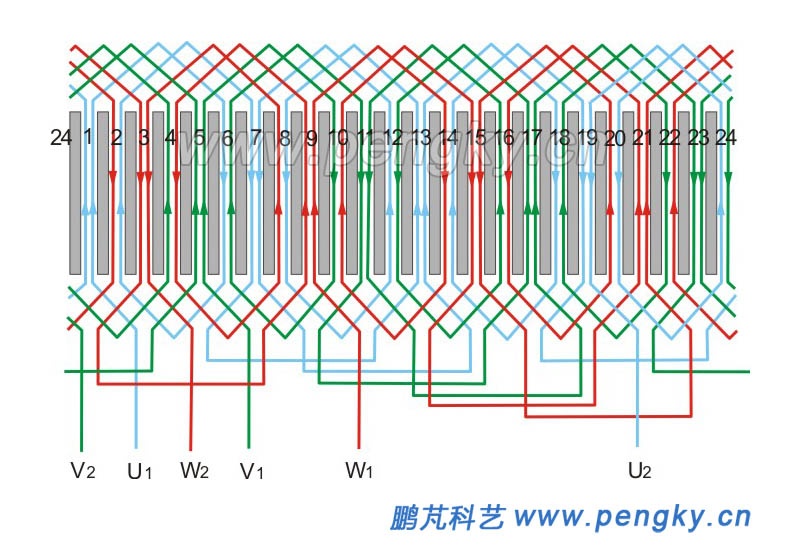

Designing these electric traction motors. Parameters such as inductance Q. Here we see a winding diagram for a 3-phase AC induction motor or brushless PM motor IPM having 4 poles and 36 slots. D L are in Meters min 025 mm For medium rating machines 2 3 mm Our effort is to keep the length of the air gap as small as possible. Conventional Windings Design In The 24 Slots Of The Single Phase Download Scientific Diagram.

Source: jmag-international.com

Source: jmag-international.com

Most stator faults are caused by insulation breakdown which leads to winding failure. The motor like squirrel cage can be frequently on track by the star to delta stator thus the stator of the motor can be connected in delta. The rotor magnetic field may be produced by permanent. Thus a high value of ac is restricted because of temp rise over load capacity and voltage of the winding as discussed above. No 15 Reading A Winding Diagram Simulation Technology For Electromechanical Design Jmag.

Source: researchgate.net

Source: researchgate.net

The two main types of AC motors are induction motors and synchronous motors. Since it is impossible for a technician to be in two places at once it is often necessary to perform diagnostic checks on a malfunctioning electric motor from the MCC where the technician has. Turn-to-turn short If the motor keeps running with stator faults a high current will flow through the windings where the problem is located. This winding could in fact be used with any AC machine including a synchronous reluctance motor or a wound-field synchronous motor or generator. The Winding Layout Of The Induction Motor Stator Download Scientific Diagram.

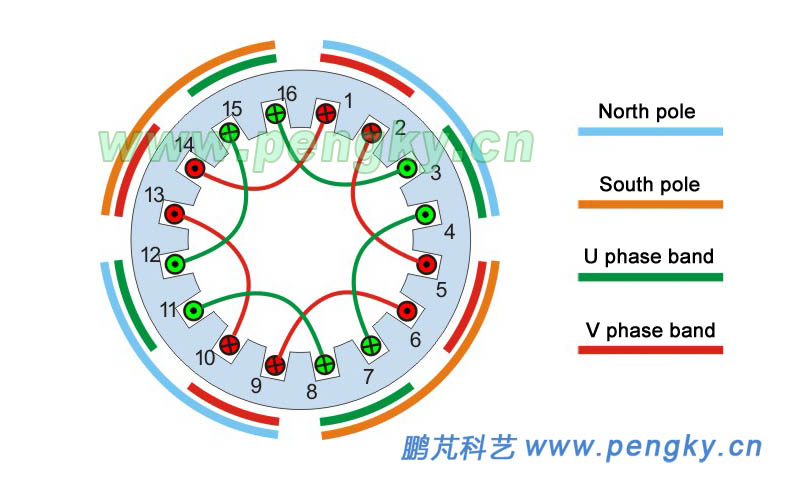

Source: pengky.cn

Source: pengky.cn

Most stator faults are caused by insulation breakdown which leads to winding failure. The rotor magnetic field may be produced by permanent. Torque 0 25 50 75 100. Introduction to Design The main purpose of designing an induction motor is to obtain the complete physical dimensions of all the parts of the machine as mentioned below to satisfy the customer specifications. Ac Motor Winding Generator Series Courseware Pengky.

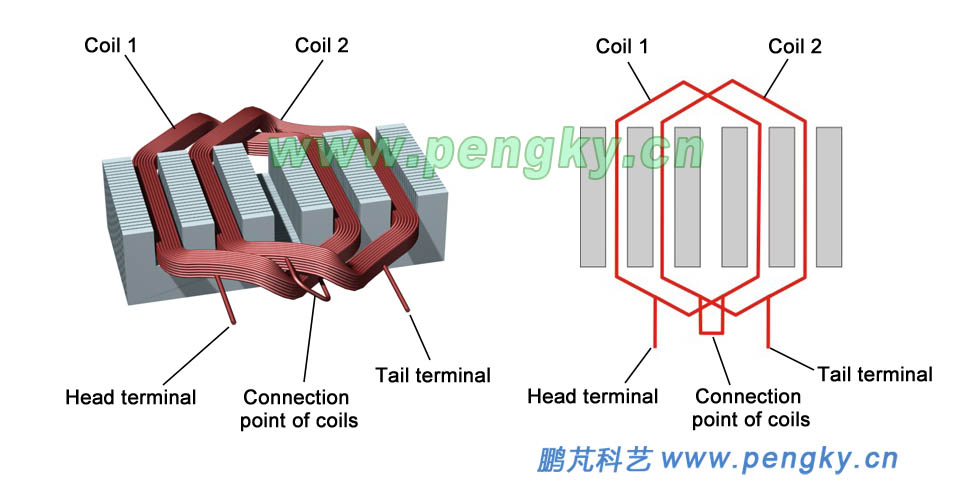

Source: windings.com

Source: windings.com

Still a popular choice for a new 400 Hz military and commercial aerospace applications. The starter and overload heater assembly for an industrial electric motor is often located quite a distance from the motor itself inside a room referred to as a motor control center or MCC. The AC motor commonly consists of two basic parts an outside stator having coils supplied with alternating current to produce a rotating magnetic field and an inside rotor attached to the output shaft producing a second rotating magnetic field. The calculation will be performed for the air-cooled three-phase motors for. Electric Motor Design Basic Tutorial Pdf Windings.

Source: windings.com

Source: windings.com

The following design details are required. The following design details are required. The calculation will be performed for the air-cooled three-phase motors for. A Shaded Pole motor is an AC single phase induction motor. Electric Motor Design Basic Tutorial Pdf Windings.

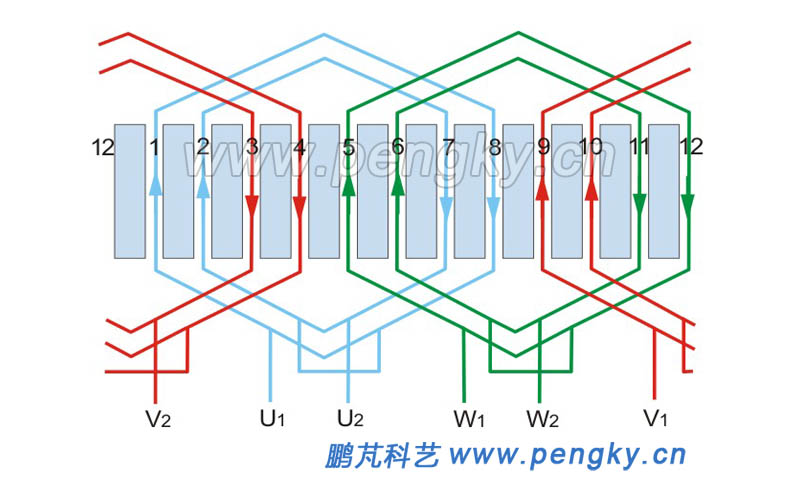

Source: pengky.cn

Source: pengky.cn

The rotor magnetic field may be produced by permanent. General-purpose motors with normal starting torques and currents and low slip. Measure resistance for each winding resistance between two different winding and resistance between winding and motors frame. The starter and overload heater assembly for an industrial electric motor is often located quite a distance from the motor itself inside a room referred to as a motor control center or MCC. Three Phase Ac Motors Winding Generator Series Courseware Pengky.

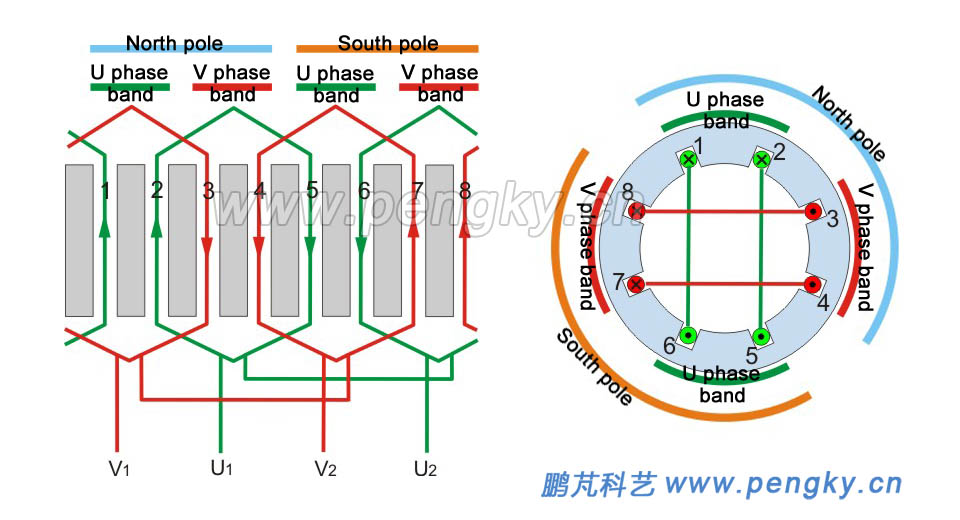

Source: pengky.cn

Source: pengky.cn

The value of ac varies between 5000 to 45000 amp. The following design details are required. Cooling is necessary to continuously transfer the heat to a cooling medium such as the air. 7 shows the radial view of the machine being studied it is a 36-slot6-pole IPM for electric vehicle applications. Ac Motor Winding Generator Series Courseware Pengky.

Source: pengky.cn

Source: pengky.cn

7 shows the radial view of the machine being studied it is a 36-slot6-pole IPM for electric vehicle applications. In electrical engineering coil winding is the manufacture of electromagnetic coils. Here we see a winding diagram for a 3-phase AC induction motor or brushless PM motor IPM having 4 poles and 36 slots. 2 Details of stator windings. Ac Motor Winding Generator Series Courseware Pengky.

Source: researchgate.net

Source: researchgate.net

Fitting the design into the Standard frame size. The two main types of AC motors are induction motors and synchronous motors. Softbit presents an easy way to design LT 3 ph TEFC squirrel cage ac electric motors with the help of AC Electric Motor Design Software. Turn-to-turn short If the motor keeps running with stator faults a high current will flow through the windings where the problem is located. Conventional Windings Design In The 24 Slots Of The Single Phase Download Scientific Diagram.

Source: windings.com

Source: windings.com

Extension to motor longevity. Problems on AC motors. This tutorial will introduce the user to the fundamental electrical and mechanical principles of AC electric induction motor design and application. Extension to motor longevity. Electric Motor Design Basic Tutorial Windings.

Source: pengky.cn

Source: pengky.cn

The current in this coil delay the phase of magnetic flux in that part of the pole in order to provide a rotating magnetic field. The different methods of cooling rotating machines are classified in the standards IEC 346 and AS 135921. The AC motor commonly consists of two basic parts an outside stator having coils supplied with alternating current to produce a rotating magnetic field and an inside rotor attached to the output shaft producing a second rotating magnetic field. The calculation will be performed for the air-cooled three-phase motors for. Three Phase Ac Motors Winding Generator Series Courseware Pengky.