The design of an aircraft metal structural repair is complicated by the requirement that an aircraft be as light as possible. It also provides the structural connection for the wings and tail assembly. Aircraft structural repair design.

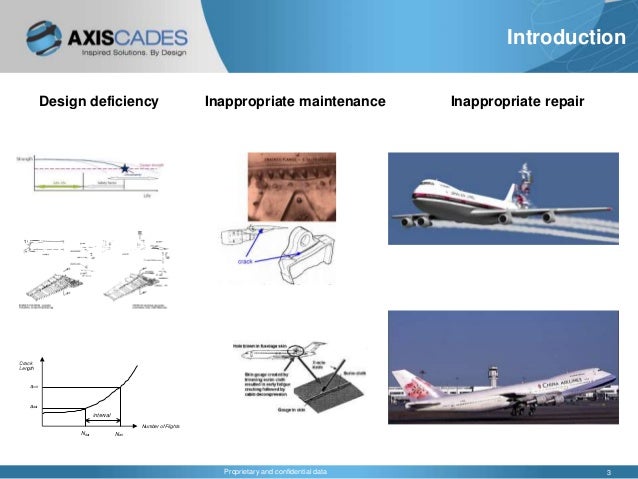

Aircraft Structural Repair Design, Several areas of improvement in the SRMs are discussed covering inappropriate and poor repair scheme design and application practices. Repair installation specifics and classification major or minor will be dictated by the nature of the structure being repaired. The design of an aircraft metal structural repair is complicated by the requirement that an aircraft be as light as possible. Aircraft construction to work in an aviation rating.

Pdf Bonded Repair Of Composite Aircraft Structures A Review Of Scientific Challenges And Opportunities From researchgate.net

Pdf Bonded Repair Of Composite Aircraft Structures A Review Of Scientific Challenges And Opportunities From researchgate.net

Identify the five basic stresses acting on an aircraft. Aircraft construction to work in an aviation rating. FDT Goals for Repair Design The fatigue and damage tolerance goals for repair design are aligned as far as possible with the goals of the original aircraft structure The above mentioned goals for repair design may influence the design and allowable of the original aircraft structure and the structural inspection program after reaching the inspection threshold Necessary. These are determined by the failure mode affecting the joint.

You will also study procedures involved in the repair of damages to the aircraft skin and structure and the type of hardware required.

Read another article:

The stake holders in this cycle include the Airframe OEMs Engine OEMs Tier 1 suppliers MRO centers and the Airliners. The entire aircraft including most notably the wings forward and rear structures were all constructed from rectangular frames that were prevented from shearing forming a parallelogram or collapsing by diagonally stretched. Structural Repair The aircraft structural repair life cycle begins at the design stage of aircraft development and continues till the aircraft retires from service. The repair design is based on static analysis. STC Twenty One also hold the privilege to design and approve structural repairs to all aircraft types.

Source: aircraft-reports.com

Source: aircraft-reports.com

Such considerations will be discussed later in the reader. Most airplane structures include a fuselage wings an empennage landing gear and a powerplant. Through an example of a chord structure repair design this paper provides an integrated methodology to design aircraft structure repairs beyond specification. Typically in the US systems engineers do not do structural analysis and therefore would not be DERs or similarly authorized by your. Ryan Navion Airplane Structural Repair Manual 1947 Aircraft Reports Aircraft Manuals Aircraft Helicopter Engines Propellers Blueprints Publications.

Source: sciencedirect.com

Source: sciencedirect.com

It also provides the structural connection for the wings and tail assembly. Help the repair community transition to repairing composites. The charter of the CACRC is to develop and improve maintenance inspection and repair of commercial aircraft composite structure and components. Repair installation specifics and classification major or minor will be dictated by the nature of the structure being repaired. Structural Repair Manual An Overview Sciencedirect Topics.

Source: aerotoolbox.com

Source: aerotoolbox.com

Although composite repairs may be of either a bolted or bonded nature. A Repair design Approval Sheet RAS is dedicated to structural damage mainly ATA structure chapters 52 to 57 and interface with systems like flight controls of ATA 27. FDT Goals for Repair Design The fatigue and damage tolerance goals for repair design are aligned as far as possible with the goals of the original aircraft structure The above mentioned goals for repair design may influence the design and allowable of the original aircraft structure and the structural inspection program after reaching the inspection threshold Necessary. Aircraft Structure Repair OEM Design Guidelines - YouTube. Introduction To Aircraft Structures Aerotoolbox.

Source: researchgate.net

Source: researchgate.net

Although composite repairs may be of either a bolted or bonded nature. Help the repair community transition to repairing composites. The Airbus process for system damages is called a Technical Adaptation TA. The entire aircraft including most notably the wings forward and rear structures were all constructed from rectangular frames that were prevented from shearing forming a parallelogram or collapsing by diagonally stretched. Pdf Aircraft Sustainment And Repair 1st Edition.

Source: aas.ag

Source: aas.ag

If we look at the early design of aircraft such as the Wright Flyer in Figure 1 there can really be no misunderstanding of the construction style. While the evolution of aluminum designs has improved the strength- to-weight ratio the industry has been seeking double-digit performance. Pieces of aircraft skin together and in a properly designed joint the rivets support more bearing or tensile load than shear load. You will also study procedures involved in the repair of damages to the aircraft skin and structure and the type of hardware required. Atlas Air Service Aircraft Structure Repair.

Source: nextantaerospace.com

Source: nextantaerospace.com

If weight were not a critical factor repairs could be made with a large margin of safety. Reliability of an aircraft depends on the quality of the design as well as the workmanship used in making the repairs. The design of an aircraft metal structural repair is complicated by the requirement that an aircraft be as light as possible. Most airplane structures include a fuselage wings an empennage landing gear and a powerplant. Structural And Component Repair Nextant Aerospace.

Source: flight-mechanic.com

Source: flight-mechanic.com

The primary factors to consider in aircraft structures are strength weight and reliability. If playback doesnt begin. Aircraft construction to work in an aviation rating. Through an example of a chord structure repair design this paper provides an integrated methodology to design aircraft structure repairs beyond specification. Repairability Of Sheet Metal Structures Part Five.

Source: flight-mechanic.com

Source: flight-mechanic.com

Most airplane structures include a fuselage wings an empennage landing gear and a powerplant. Figure 1 shows various phases of the structural repair cycle. I never meant to restrict the discussion to the US. The repair design is based on static analysis. Repairability Of Sheet Metal Structures Part Five.

Source: sciencedirect.com

Source: sciencedirect.com

Speak to the Team. If we look at the early design of aircraft such as the Wright Flyer in Figure 1 there can really be no misunderstanding of the construction style. Structural Design Reader AE2-521N Version 102 Mostafa Abdalla Roeland De Breuker. STC Twenty One has the approval privilege to design changes to primary secondary and tertiary structure on large and small aircraft and rotorcraft. Structural Repair Manual An Overview Sciencedirect Topics.

Source: aas.ag

Source: aas.ag

Reliability of an aircraft depends on the quality of the design as well as the workmanship used in making the repairs. STRUCTURAL STRESS LEARNING OBJECTIVE. This leads to a description of the aircraft structure repair manuals SRM typically explanation of how to conduct a composite structural repair is applied. Identify the five basic stresses acting on an aircraft. Atlas Air Service Aircraft Structure Repair.

Source: sciencedirect.com

Source: sciencedirect.com

It is the responsibility of the operator to ensure that the repair installation documentation and any required engineering action evaluation design analysis etc meet the regulations of the faa or. Repair installation specifics and classification major or minor will be dictated by the nature of the structure being repaired. FDT Goals for Repair Design The fatigue and damage tolerance goals for repair design are aligned as far as possible with the goals of the original aircraft structure The above mentioned goals for repair design may influence the design and allowable of the original aircraft structure and the structural inspection program after reaching the inspection threshold Necessary. Aircraft Structure Repair OEM Design Guidelines. Mechanically Fastened Repair An Overview Sciencedirect Topics.

Source: flight-mechanic.com

Source: flight-mechanic.com

These are determined by the failure mode affecting the joint. You said that you were in systems engineering. The stake holders in this cycle include the Airframe OEMs Engine OEMs Tier 1 suppliers MRO centers and the Airliners. Speak to the Team. Repairability Of Sheet Metal Structures Part Three.

Source: slideshare.net

Source: slideshare.net

Aircraft construction to work in an aviation rating. Most airplane structures include a fuselage wings an empennage landing gear and a powerplant. You will study the design and construction of aircraft parts and assemblies metals used in the construction and the metal qualities and stresses involved. If playback doesnt begin. Structural Repair Of Aircraft.

Source: aas.ag

Source: aas.ag

Identify the five basic stresses acting on an aircraft. You will also study procedures involved in the repair of damages to the aircraft skin and structure and the type of hardware required. Composite repair is given. While the evolution of aluminum designs has improved the strength- to-weight ratio the industry has been seeking double-digit performance. Atlas Air Service Aircraft Structure Repair.

Source: flight-mechanic.com

Source: flight-mechanic.com

The second section of the reader is dedicated. Aircraft Structure Repair OEM Design Guidelines - YouTube. The entire aircraft including most notably the wings forward and rear structures were all constructed from rectangular frames that were prevented from shearing forming a parallelogram or collapsing by diagonally stretched. These factors determine the requirements to be met by any material used to construct or repair the aircraft. Repairability Of Sheet Metal Structures Part Three.