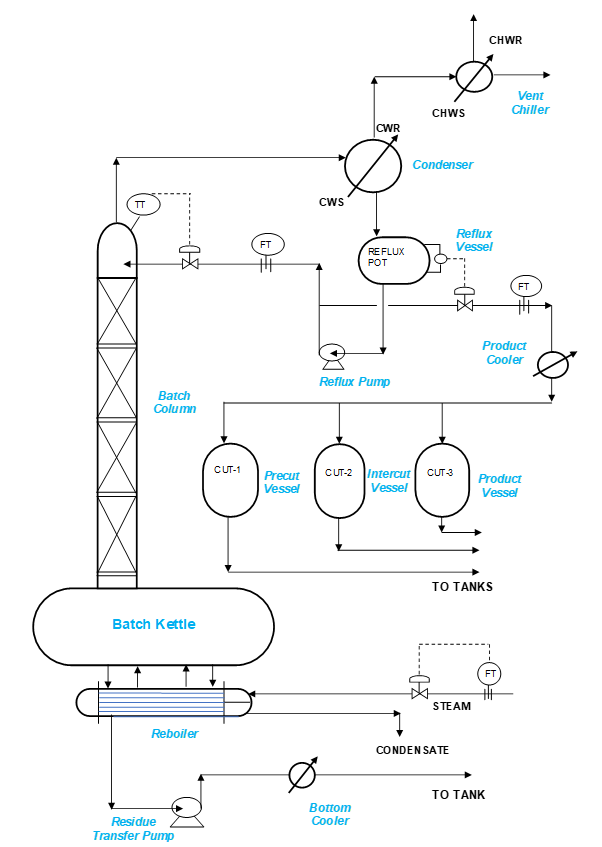

Batch distillation column as shown in Figure 51a. R LD 6. Batch distillation design and operation.

Batch Distillation Design And Operation, The design consisted of a process flow diagram a layout and a summary of all equipment required for the operation of the distillery. Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. Sample Chapters Foreword 87 KB Chapter 1. Number of stages or plates in the column section and thereby the column height 2.

Distillation Reflux Principle Distilling Alcohol Distillation Moonshine Still From pinterest.com

Distillation Reflux Principle Distilling Alcohol Distillation Moonshine Still From pinterest.com

The efforts include both the design and operation of batch distillation. Logsdon and Biegler 1993. Batch Distillation of Spirits. Bernot et al 1991 1993.

Because this batch column essentially performs the rectifying operation it is often referred to as a batch rectifier.

Read another article:

Design and Operation presents excellent important contributions of many researchers from around the globe including those of the author and his co-workers. Batch distillation column as shown in Figure 51a. 4 Operation under finite reflux ratio without solvent. Logsdon and Biegler 1993. Techniques for the dynamic simulation and optimization of the operation are reviewed in particular the control vector parameterization.

Source: chemengghelp.com

Source: chemengghelp.com

Because this batch column essentially performs the rectifying operation it is often referred to as a batch rectifier. Batch distillation1 is the oldest separation process and the most widely used unit operation in pharmaceutical and specialty chemical industries. Techniques for the dynamic simulation and optimization of the operation are reviewed in particular the control vector parameterization. 2 Operation under total reflux with sol-vent-feedingoo S0. Batch Distillation Column Operation Controls Chemengghelp.

Source: pinterest.com

Source: pinterest.com

Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. 4 Operation under finite reflux ratio without solvent. The primary objective in a batch distillation is to minimize both the batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation. 3 Operation under finite reflux ratio with sol-vent-feeding0. Dephlegmator Distilling Alcohol How To Make Vodka Moonshine Still Plans.

Bernot et al 1991 1993. It is perhaps the oldest technology for separating or. Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. Design of batch distillation. 2.

Source: pinterest.com

Source: pinterest.com

21 Conventional Batch Distillation Column 4 22 Configuration of Batch Distillation Column 5 31 Configuration of Batch Distillation Column in UTAR FES Unit Operation Laboratory 15 41 McCabe Thiele Diagram and Stepping from x D 082 082 19 42 Graph of 1 x. This paper considers for the first time the simultaneous multi-objective optimisation of design and operation of batch distillation as well as of batch hybrid distillationpervaporation processes. Control variables operating decisions and objectives are identified. Design And Operation Optimisation. Distillation Reflux Principle Distilling Alcohol Distillation Moonshine Still.

Source: pinterest.com

Source: pinterest.com

Control variables operating decisions and objectives are identified. The batch distillation process has existed for many centuries. Reboiler size batch size and heat transfer area 4. R LD 6. Mother Earth Alcohol Fuel Chapter 8 Still Plans Moonshine Still Moonshine Still Plans Whiskey Still.

Source: pinterest.com

Source: pinterest.com

Batch distillation column as shown in Figure 51a. Sample Chapters Foreword 87 KB Chapter 1. R LD 6. 1 SCOPE This Engineering Guide sets out the factors which can influence the design of a batch still facility. Fractionating Column Distilling Alcohol Homemade Alcohol Beer Brewing Kits.

Source: nzifst.org.nz

Source: nzifst.org.nz

The process variables are interdependent as determined by the mass and energy balances and the mode of operation. Number of stages or plates in the column section and thereby the column height 2. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. It is perhaps the oldest technology for separating or. Unit Operations In Food Processing R L Earle.

Source: researchgate.net

Source: researchgate.net

The most outstanding feature of batch distillation is its flexibility in operation. Whilst this is a particularly valid approach when the vapor-liquid equilibria are unknown it relies on both experience and availability of suitable plant to get a practical separation scheme. A batch still with a 50 gallon pot. 2 Operation under total reflux with sol-vent-feedingoo S0. Batch Distillation With Rectifying Column Download Scientific Diagram.

Source: pinterest.com

Source: pinterest.com

The efforts include both the design and operation of batch distillation. The design consisted of a process flow diagram a layout and a summary of all equipment required for the operation of the distillery. A batch still with a 50 gallon pot. Bernot et al 1991 1993. Home Distillation Of Alcohol Homemade Alcohol To Drink Distillation Homemade Alcohol Home Brewing.

Source: pinterest.com

Source: pinterest.com

However the design of a batch distillation system is more complicated because of the transient nature of the operation and because there may be several ways in which the overall separations required may be accomplished. R LD 6. Batch distillation1 is the oldest separation process and the most widely used unit operation in pharmaceutical and specialty chemical industries. 2 Operation under total reflux with sol-vent-feedingoo S0. Image Result For Copper Reflux Still Plans Pot Still Moonshine Still Plans Homemade Still.

Source: pinterest.com

Source: pinterest.com

The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Mujtaba and Macchietto 1993. R LD 6. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Homemade Reflux Distilling Columns Distilling Alcohol Moonshine Recipes Alcohol Still.

Source: pinterest.com

Source: pinterest.com

Conventional Batch Distillation 58 421 Rayleigh Model Model Type I 58 422 Short-cut Model- Model Type II 59 423 Simple Model- Model Type I11 63 424 Rigorous Model -Model Type IV 68 425 Rigorous Model wt Chemical Reactions -Model Type V 79 ih 43 Models for Unconventional Batch Distillation 85 431 Continuous Column for Batch Distillation 85 432 Inverted Batch. Whilst this is a particularly valid approach when the vapor-liquid equilibria are unknown it relies on both experience and availability of suitable plant to get a practical separation scheme. The batch distillation process. Control variables operating decisions and objectives are identified. Sieve Design Distillation Distilling Alcohol Homemade Alcohol.

Source: pinterest.com

Source: pinterest.com

Logsdon and Biegler 1993. It is perhaps the oldest technology for separating or. Reflux ratio D L R. 3 Operation under finite reflux ratio with sol-vent-feeding0. Collected Information Regarding The Construction Of A Boka Bob Still Reflux Still Distilling Alcohol Moonshine Still Plans.

Source: pinterest.com

Source: pinterest.com

Reboiler size batch size and heat transfer area 4. Bernot et al 1991 1993. Batch distillation1 is the oldest separation process and the most widely used unit operation in pharmaceutical and specialty chemical industries. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Click For A Larger View Moonshine Still Plans Reflux Still Alcohol Still.

Source: pinterest.com

Source: pinterest.com

Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. Imperial College Press Jan 1 2004 - Technology Engineering - 396 pages. Bernot et al 1991 1993. Control variables operating decisions and objectives are identified. Continuous Distillation Wikipedia The Free Encyclopedia Distillation Distilling Alcohol Chemical Engineering.