The current casthouse design was placed in service following the second reline in the fall of 1979. We cannot guarantee that every book is in the library. Blast furnace design book.

Blast Furnace Design Book, This book includes a set of equations that accurately describe stoichiometric and enthalpy balances for the process and which are consistent with observed temperatures and. Hot air is blasted through the bottom. New requirements around H 2 injection CO 2 reductions and financial constraints add extra layers of complexity to these decisions while shortcuts and poor choices can lead to expensive unplanned stoppages. Blast Furnaces represents a continuation of but also a counterpoint to the Bechers earlier book Watertowers.

Blast Furnace Ironmaking Analysis Control And Optimization Cameron Ian Sukhram Mitren Lefebvre Kyle Davenport William 9780128142271 Amazon Com Books From amazon.com

Blast Furnace Ironmaking Analysis Control And Optimization Cameron Ian Sukhram Mitren Lefebvre Kyle Davenport William 9780128142271 Amazon Com Books From amazon.com

If mined without a pickaxe it does not drop anything. Hearth capable of producing over 9000 tons of hot metal per day. Oxygen in the air reacts with coke to give carbon dioxide. Blast furnaces can generate in any armorer house.

The Iron Blast Furnace.

Read another article:

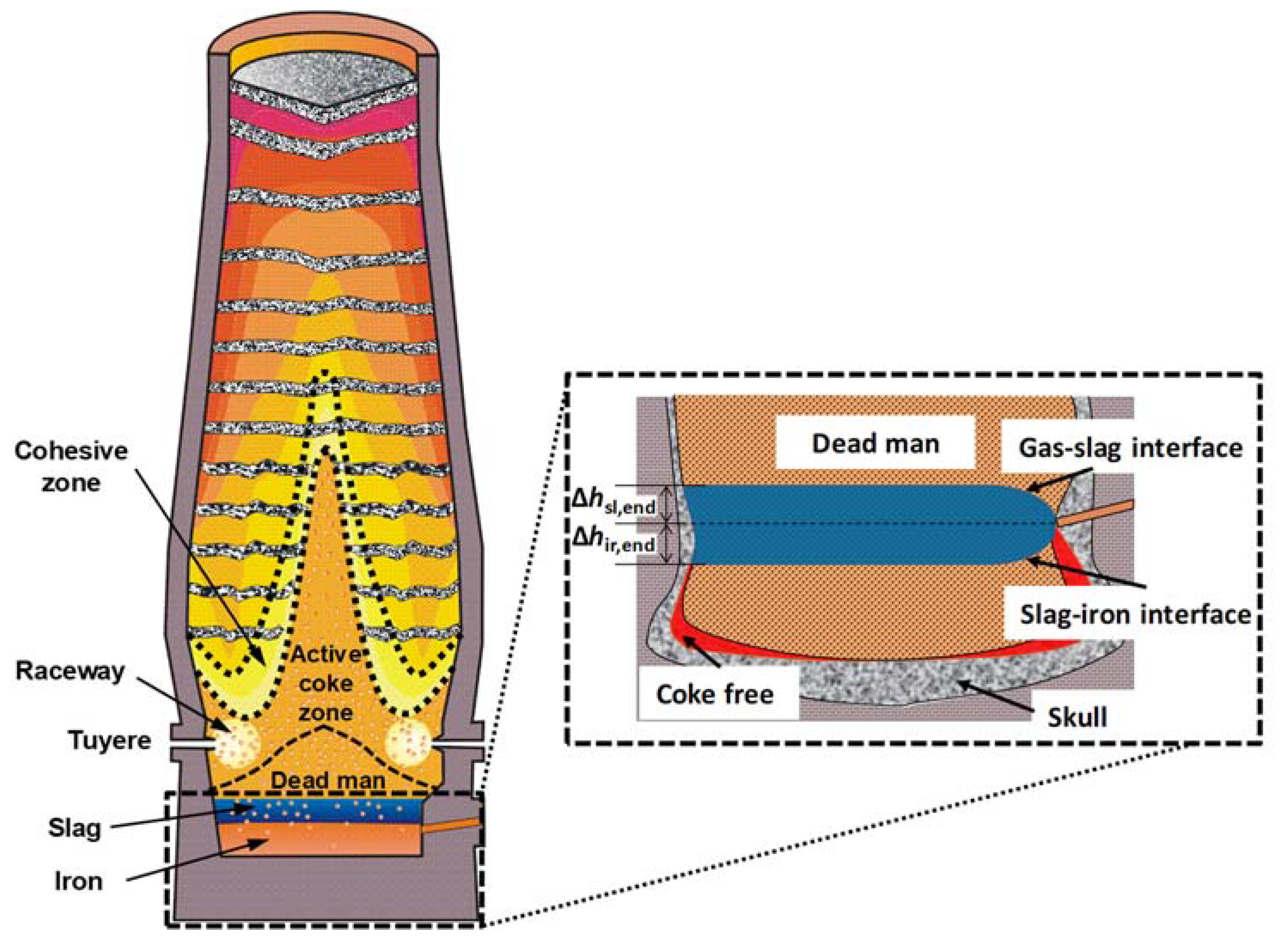

Blast furnace profile 11 Blast furnace stove and gas cleaning units instrumentation 12 Refractory used in blast furnace and stove 13 Blast furnace Operations 14 Material Balance Module II 15 Reduction of Iron Ore 16 Fe -C O Fe O H phase equilibria 17 Zones in Blast Furnace Reactions in stack. Unlike flexible defences popular everywhere else in the world the rigid articulated exoskeleton of a suit of armour was a more extravagant and less adaptable means of personal protection. The Iron Blast Furnace. In a blast furnace fuel ores and flux are continuously supplied through the top of the furnace while a hot blast of air sometimes with. It required greater metallurgical resources to make but offered far better protection.

Source: sciencedirect.com

Source: sciencedirect.com

Oxygen in the air reacts with coke to give carbon dioxide. We cannot guarantee that every book is in the library. The Iron Blast Furnace. The blast furnace is around 30 metres high and lined with fireproof bricks. Blast Furnace Feedstock And Coke Oven Chemical Feedstock Sciencedirect.

Source: za.pinterest.com

Source: za.pinterest.com

Hot air is blasted through the bottom. Unlike flexible defences popular everywhere else in the world the rigid articulated exoskeleton of a suit of armour was a more extravagant and less adaptable means of personal protection. Industrial and Process Furnaces. Theory and Practice presents theoretical experimental and operational evidence about the iron blast furnace as well as a mathematical description of its operation. Animation Of How And Old Blast Furnace Worked Educational Practical Industrious Blast Furnace Furnace Water Wheel.

Source: pinterest.com

Source: pinterest.com

Ad Discover 19 Million Books with Free Delivery - No Minimum Spend. OPERATIONSBASED DESIGN CONSIDERATIONS Edo Engel1 Victor van Straaten2 Roman Vaynshteyn3 Abstract Whereas only a handful of decades ago typical blast furnace working volumes were below 1000 m³ such furnaces are currently designated compact or even mini blast furnaces. Mississauga Canada Hatch is delighted to announce the publication of a new technical reference book Blast Furnace Ironmaking. Theory and practice Biswas A. The Entire History Of Steel Blast Furnace Steel Worker Steel.

Source: amazon.com

Source: amazon.com

The suit of armour distinguishes the European Middle Ages Renaissance from all other periods and cultures. Full PDF Package Download Full PDF Package. Blast furnaces drop their contents when broken. Ad Discover 19 Million Books with Free Delivery - No Minimum Spend. Blast Furnace Ironmaking Analysis Control And Optimization Cameron Ian Sukhram Mitren Lefebvre Kyle Davenport William 9780128142271 Amazon Com Books.

Source: sciencedirect.com

Source: sciencedirect.com

Blast Furnace and Process Description 3D Model. It required greater metallurgical resources to make but offered far better protection. Blast furnace iron has limited engineering applications. Step 2a - the Blast Furnace The sinter is added through a hopper at the top of the Blast Furnace. Blast Furnace An Overview Sciencedirect Topics.

Source: pinterest.com

Source: pinterest.com

Blast furnaces drop their contents when broken. Blast Furnace and Process Description 3D Model. Principles Design and Operation. Traditionally blast furnace hearths are lined with high thermal conductive carbon-based materials. Make Build Mini Cupola Blast Furnace Melt Metals Iron Aluminum Brass How To Metal Working Metal Working Projects Metal Tree.

Source: pinterest.com

Source: pinterest.com

Placed inside the carbon lining the concept of the SG Ceramic Cup is an example where a specific advanced design and material quality render significant benefit to blast furnace operators in terms of lifetime extension and operational efficiency. Step 2a - the Blast Furnace The sinter is added through a hopper at the top of the Blast Furnace. The current casthouse design was placed in service following the second reline in the fall of 1979. Blast furnace iron has limited engineering applications. Pin On Cool Stuff.

Source: sciencedirect.com

Source: sciencedirect.com

Read as many books as you like Personal use and Join Over 150000 Happy Readers. Theory and Practice presents the significant role of iron blast furnace by which iron is efficiently and rapidly reduced from ore and it is the basis for all primary steelmaking. MODERN MINI AND COMPACT BLAST FURNACES. With blast furnace service lives typically extending to 20 years or more it imperative that the correct lining design is selected and maintained. Ironmaking Process An Overview Sciencedirect Topics.

Source: pinterest.com

Source: pinterest.com

In order to read online Blast Furnace Ironmaking textbook you need to create a FREE account. Download Blast Furnace Ironmaking Book For Free in PDF EPUB. A blast furnace can be picked up by any pickaxe. Cooling systems developed from simple shower spray and. All About Blast Furnace Blast Furnace Steel Worker Furnace.

Source: pinterest.com

Source: pinterest.com

It required greater metallurgical resources to make but offered far better protection. In a blast furnace fuel ores and flux are continuously supplied through the top of the furnace while a hot blast of air sometimes with. Articleosti_367896 title New concepts and designs for blast furnace linings and cooling systems author Carmichael I F abstractNote In the 1960s concurrent with major technological developments in blast furnace operation cooling became increasingly important in extending furnace campaign life. FREE shipping on qualifying offers. New Pictures Of My Steel Mill Blast Furnace Model Railroad Hobbyist Magazine Model Railroad Ho Model Trains Blast Furnace.

Source: pinterest.com

Source: pinterest.com

37 Full PDFs related to this paper. Blast furnace iron has limited engineering applications. The current casthouse design was placed in service following the second reline in the fall of 1979. In a blast furnace fuel ores and flux are continuously supplied through the top of the furnace while a hot blast of air sometimes with. Picture Blast Furnace Furnace Iron Ore.

Source: pinterest.com

Source: pinterest.com

13 Blast Furnace at US Steels Gary Works is a 35 tuyere furnace with a 365 ft. MODERN MINI AND COMPACT BLAST FURNACES. Theory and Practice presents theoretical experimental and operational evidence about the iron blast furnace as well as a mathematical description of its operation. 37 Full PDFs related to this paper. Extraction Of Iron The Blast Furnace Free Zimsec Revision Notes And Past Exam Papers Blast Furnace Chemistry Furnace.

Source: mdpi.com

Source: mdpi.com

Placed inside the carbon lining the concept of the SG Ceramic Cup is an example where a specific advanced design and material quality render significant benefit to blast furnace operators in terms of lifetime extension and operational efficiency. We cannot guarantee that every book is in the library. Hot air is blasted through the bottom. The design of the hopper stops gases escaping through the top as sinter is added. Processes Free Full Text Dead Man Behavior In The Blast Furnace Hearth A Brief Review Html.

Source: pinterest.com

Source: pinterest.com

Step 2a - the Blast Furnace The sinter is added through a hopper at the top of the Blast Furnace. Most blast furnace iron is the raw material for oxygen steelmaking where the molten iron is refined to produce the worlds most popular metal for engineering applicationsrolled steel. OPERATIONSBASED DESIGN CONSIDERATIONS Edo Engel1 Victor van Straaten2 Roman Vaynshteyn3 Abstract Whereas only a handful of decades ago typical blast furnace working volumes were below 1000 m³ such furnaces are currently designated compact or even mini blast furnaces. C s O 2 g CO2 g The limestone breaks down to form carbon dioxide. Number 9 By Daniel Ashe Photograph Zatista Zatista Numbers Typography Numbers.

Source: newsteelconstruction.com

Source: newsteelconstruction.com

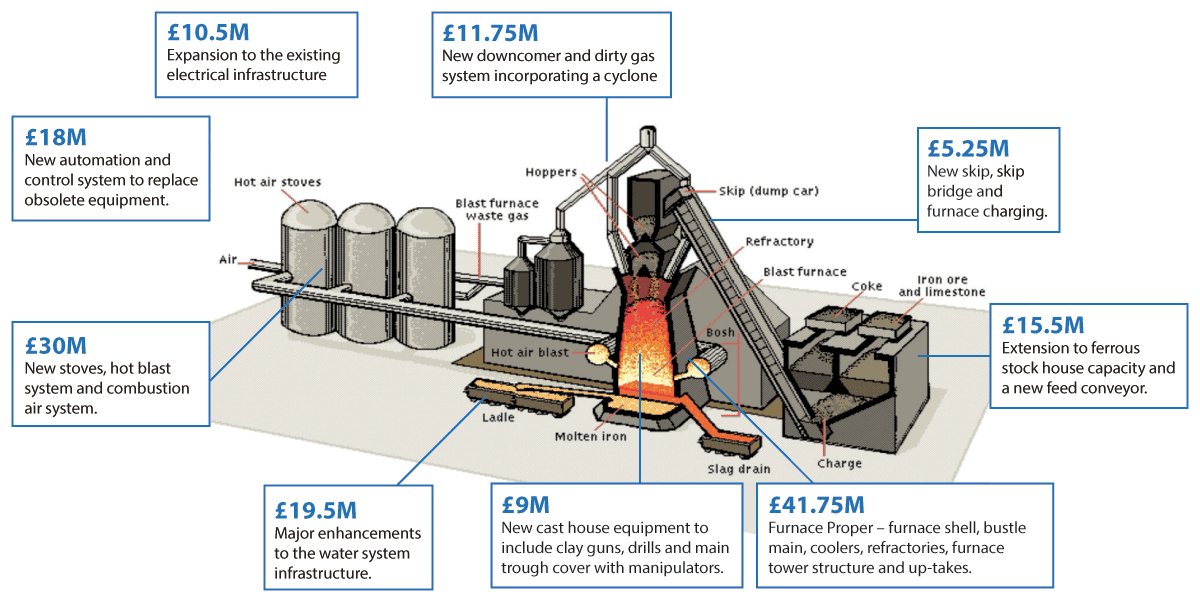

This book discusses the importance of blast-furnace process as a complete operation. Blast refers to the combustion air being forced or supplied above atmospheric pressure. Ad Discover 19 Million Books with Free Delivery - No Minimum Spend. Theory and Practice presents the significant role of iron blast furnace by which iron is efficiently and rapidly reduced from ore and it is the basis for all primary steelmaking. Furnace Ready For Blast Off Newsteelconstruction Com.